Auto Parts

Product Display

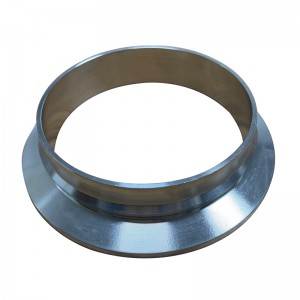

Square Flanges

product description:

Standard:

ANSI/ASME:

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN:

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S:

BS4504, BS4504, BS1560, BS10, etc

The square flange is used to close ends of piping systems. The Square Flange provides a dependable and long lasting isolation point. The Square Flange is similar in diameter to a standard flange and the laying length is compact, making it easily adaptable for your piping systems.

Square Flanges Material:

Stainless Steel Square Flanges : ASTM A182, A240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Carbon Steel Square Flanges : ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70

Alloy Steel Square Flanges : ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Duplex Steel Square Flanges : ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Super Duplex Square Flanges : ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61

Nickel Alloy Square Flanges :Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II)

Copper Alloy Square Flanges : UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu-Ni-70/30)

Low Temperature Carbon Steel Square Flanges : ASTM A350, LF2, LF3

Applications Of Square Flanges

Square Flanges are used in Chemical and petrochemical processing.

Square Flanges are used in electronics.

Square Flanges are used in processing equipment for maintaining product purity in handling foods, synthetic fibers.

Square Flanges are used in marine and offshore engineering.

Dimensions of Square Flanges

WHAT IS A HYDRAULIC FLANGE ?

A hydraulic flange properly directs the flow of a liquid medium, usually oil, through your hydraulic system. The direction of the oil flow is determined by the position of a spool. A hydraulic system can only function - as per requirements - by using flanges. Thus, you should always look for the correct type of hydraulic flange to serve your intended purpose. The required size is determined by the maximum flow of the hydraulic system through the flange and the maximum system pressure.

Hydraulic flange are available in a variety of sizes and according to multiple International Standards. Hydraulic flanges are available with many different mounting styles: e.g. mounting in pipe lines, with threaded connection as cartridge flanges, subplate mounting or flanged mounting. Hydraulic flanges are subdivided into three main categories: directional control flange, pressure control flange and flow control flanges. All flanges operate a different function in the hydraulic system.

Different flange function in different ways. Check flanges permit free flow in one direction and block flow in the opposite direction. The directional control flange is used to pass on the pressure medium (i.e. flow) in an orderly fashion to a particular direction. Pressure control flange switch (or control) at a certain pressure; the switching pressure may be adjusted on the flange. Flow control flanges regulate the flow this is done by adjusting the size of the bores (orifices)

Packaging & Delivery:

| Selling Units: | Single item | Single package size: | 1200X800X600 cm |

| Package Type: | Plywood Cases. |

Lead Time:

| Quantity(Pieces) | 1 - 50 | 51 - 500 | 501 - 2000 | >2000 |

| Est. Time(days) | 3 | 7 | 10 | To be negotiated |

Transport: By ocean/By air

After Service:

If you have received any unqualified part, please show us the pictures, after our engineers and QC department check ,we will choose to help you repair or redo within 10~15 days according to rejected quantities.